Stepper Motor Driver Price-Sequre 42 Two Phase Stepper Motor

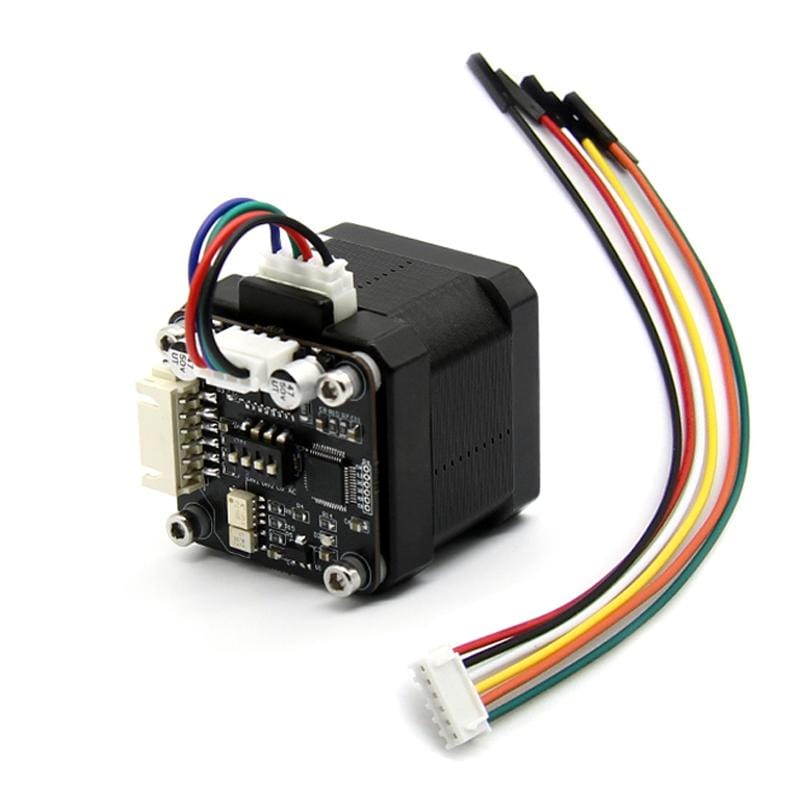

Nema 17 Stepper Motor STM32 Closed-loop 42 Servo Stepper Motor Kit With Driver Board | Suitable for 3D Printing | Compatible Mechaduino

42 Stepper Motor Firmware Download

DIY Large 60x70cm 3D Printer with CLOSE-LOOP Stepper

How to wiring Close-loop motor with MKS GEN L

Closed Loop Stepper Motor Explained using Arduino

Motor Parameters:

Product Name: 42 two-phase stepper motor

Model number :17HS4401

Step angle : 1.8 °

Maximum no-load starting frequency : ≥ 1400 PPS

Rated voltage 3.6V

Maximum no-load operating frequency : ≥ 4000 PPS

Rated current : 1.5A / phase

Phase inductance :3.7 × (1 + 20%) mH

Holding torque : ≥420 mN.m

Phase resistance : 2.4 × (1 + 15%) Ω / phase

Positioning torque : 15 mN.m REF

Electric strength : AC600V / 1mA / 1S

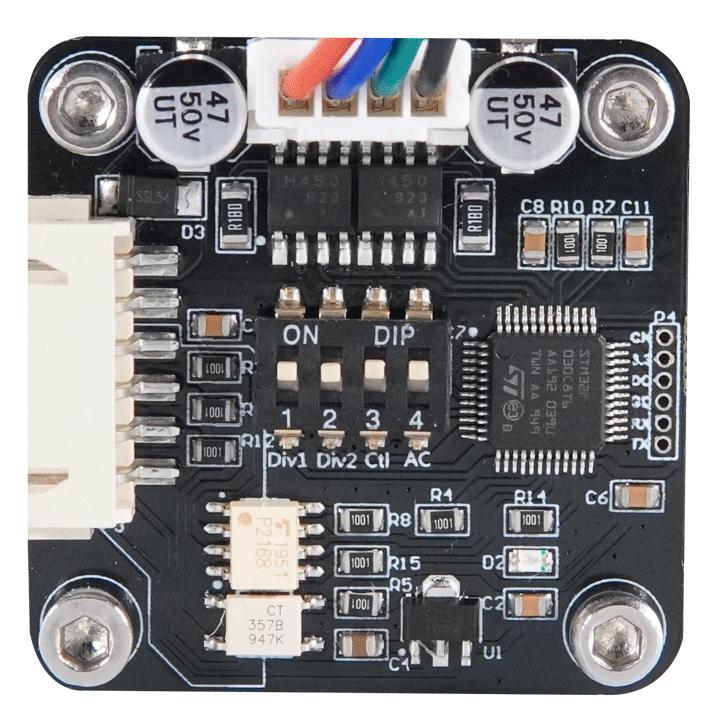

Wiring Instructions:

1.VCC : Connect 12-30V power supply ( Refer to the working voltage of the motor, general 24V )

2.GND: Ground wire

3.CLK : Control signal (Connected to pulse input )

4.DIR: Direction control signal ( Floating forward, ground reverse )

5.ENA: Connect to enable signal ( Default enable, grounding stops working )

6.P2: Connect one phase to the motor on each side ( Refer to the motor parameter description, the motor is divided into two phases AB, pins 1 and 2 are connected to one phase, and pins 3 and 4 are connected to the other phase. )

DIP switch {ON (1) / OFF (0)}:

1.Div1, Div2 control pulse frequency division

(1) 00: 4 subdivision

(2) 10: 8 subdivision

(3) 01:16 subdivision

(4) 11:32 subdivision

2.Ctl setting control mode, open-loop / closed-loop

(1) 0 : Open-loop mode

(2) 1 : Closed-loop mode

3.AC setting calibration

Turn the AC to position 1, and turn on the power. The LED blinks 3 times to start automatic calibration. The motor shaft rotates counterclockwise for one cycle and then clockwise for one cycle. The system automatic calibration complete and the LED continues to flash. The AC dial returns to position 0, and then restart power.

Application examples:

- 3D printing with fine closed-loop positioning

- Optical precision aiming (Laser, telescope, camera gimbal, camera slider etc.)

- Speed loop record player

- Force feedback / impedance control robot

- Force feedback of game controller

- Adjustable mechanical impedance: virtual spring, damper, etc.

- Electric transmission device between two axes such as CNC machine tools

- Gravity elimination (eg: offset gravity torque on the robot arm, etc.)

- Load detection and feature description (Used as a balance, etc.

- Paper towel / TP distributor

- Variable load (Brake, generator, etc.)

- Valve control (Automated garden hose, etc.)

Package includes :

1× machine

1× 6P cable

1× instruction manual

Note: The product is installed and tested by our professional staff, and you can use it

normally when you receive the goods.

Package Detail:

Product size: 75 (length) * 55mm (maximum diameter)

Net weight: 305g

Box size: 135 * 80 * 90mm

Weight after packing: 350g

Tips: If you want to distribute our products, please contact us and we’ll be glad to send you our price list.

To the Buyer: Dear customers, thanks for the support to Sequre. After your order is confirmed, please note the declare value on the checkout page, so that we can deliver the goods to you quickly.Wish you a happy life.

Sequre Team

Shipping Policy

Shipping Time:

Most orders received before 6:00PM will ship the same day, provided the product ordered is in stock. Most orders received after 6:00 PM will ship the next business day. Orders are not processed or shipped on Sunday, except by prior arrangement. Buyer pays for shipping fee if required at checkout.

We cannot guarantee when an order will arrive. Consider any shipping or transit time offered to you by SEQURE or other parties only as an estimate. We encourage you to order in a timely fashion to avoid delays caused by shipping or product availability.

DHL shipments do not offer guaranteed delivery transit times. Occasionally DHL misroutes shipments. Any shipment listed as being misrouted or marked as return to sender in error will not be re-shipped until the package arrives at SEQURE headquarters.

In situations where products are in high demand, processing time can take longer than 3 working days.

Estimated Shipping Time:

Registered Mail: 7-20 working days

Express Shipping 3-7 working days

*Please note that these are estimated delivery times only, therefore SEQURE is not guaranteeing delivery dates.

Wrong Address:

Shipments will be sent to the address entered on our web page during checkout. SEQURE cannot be held responsible if the incorrect shipping address is entered by the customer during checkout. We cannot change shipping addresses after the order has been placed, as the address information you enter is used as part of the fraud checks and fraud prevention. The shipping address you enter on our web page takes precedence over addresses listed in the order comments or entered in PayPal. If additional fees are required to re-ship packages due to address errors, those fees may be passed on to the customer. SEQURE reserves the right to cancel and refund any orders that have indicators showing there is some risk that a stolen credit card is possibly being used. Paying through PayPal is recommended for new customers purchasing high value items to prevent possible order cancelations or delays.

NOTE: FedEx/UPS/DHL express can not ship to P.O Boxes.

Signature requirements None of the mail services offered by SEQURE require a signature on delivery of your package. Only in certain cases and in the sole discretion of SEQURE will a signature be required.

International, Customs, Duties, and "Return to Sender" Packages

We cannot hold the package which is on the way to you. When the package have been handed over to the courier company, we do not accept refunds application for any reason.

For orders shipped outside the China, you are solely responsible for any and all import duties your local customs office may impose on your order. If a package is returned to SEQURE due to the Mail Carrier's inability to collect customs duties or deliver the package to your provided ship-to address, SEQURE will not refund a) shipping costs from SEQURE to your location and b) the cost of returning the package back to SEQURE, when and if the package is returned to SEQURE. In the event that a package can not be delivered due to the issues listed in this paragraph and the overall value of your order is less than the cost of returning the package back to SEQURE, SEQURE may select to 'abandon' the package. If your package is abandoned, you will not receive a refund.

Refund policy

Return Policy (RMA):

*RMA# (to be issued to you)

*30 days for return from the date of order delivered

*Purchasing record on sequremall.com is required

*Shipment of incorrect product by fulfillment mistakes will be rejected.

*Returned items that are rendered unsellable as a new product will be rejected.

Returns of opened packages may be accepted under some rare situations, but may be subject to a restocking fee or rejected depending on the condition of the items.

Customers returning defective items will receive either a replacement, a coupon, or a refund. Orders are eligible for refund up to 30 days after the order delivered, otherwise coupon or replacement may be issued.

Returns of products in good working order will receive a refund for the price of the item only, not the shipping costs.

Full refund requires:

*Within 30 days of order delivered

*Product in new condition with no wear

*All packaging included and intact

As parts of complex systems, failure of one component can result in a crash or damage to other items. SEQURE is not responsible in any way, for damage to other equipment due to a failure of a component in a system.

To complete your return, we require a receipt or proof of purchase.

Take pictures of the product in its current state, so that we can ensure whether there are missing parts or other damage before returning the product.

There are certain situations where only partial refunds are granted (if applicable) Any item not in its original condition, is damaged or missing parts for reasons not due to our error.

Any item that is returned more than 30 days after delivery.

Refunds (if applicable):

Once your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.

If you are approved, then your refund will be processed, and a credit will automatically be applied to your credit card or original method of payment, within a certain amount of days.

Late or missing refunds (if applicable):

If you haven’t received a refund yet, first check your bank account again.

Then contact your credit card company, it may take some time before your refund is officially posted.

Next contact your bank. There is often some processing time before a refund is posted. If you’ve done all of this and you still have not received your refund yet, please contact us at sequremall.com.

Sale items (if applicable):

Only regular priced items may be refunded, unfortunately sale items cannot be refunded.

Exchanges (if applicable):

We only replace items if they are defective or damaged. If you need to exchange it for the same item, send us an email at sequremall.com for return address, recipient information and further communication.Please do not return the items before contacting us.

Shipping:

To return your product,ship the product to the address we provide you. You will be responsible for paying for your own shipping costs for returning your item. Shipping costs are non-refundable. If you receive a refund, the cost of return shipping will be deducted from your refund.

Depending on where you live, the time it may take for your exchanged product to reach you, may vary.

If you are shipping an item over $50, you should consider using a trackable shipping service or purchasing shipping insurance. We don’t guarantee that we will receive your returned item.

Custom OEM Solutions

We Offer a Uniquely Complete Design & Manufacture Service for OEM's Custom engineering is at the heart of our business. As an OEM customer we can offer you a complete design & manufacture service, often creating entirely new and technologically advanced products that meet your exact needs and requirements.

In-House Design Team and Lab

One of our key assets is our team of design and development engineers – in total, we have six engineers supported by three technicians – with a fully equipped laboratory, that is used when developing products and making prototypes.Cost Effective With Product Assurance

To make best use of our design resources, we are often able to modify an existing product to meet your specific needs, and we can call upon a design portfolio of over 10 different designs to help us in this customisation?work. This can provides a cost effective solution with the assurance of tried and tested design platform.

Flexible & Timely Manufacture

Our state of the art manufacturing facilities offer reliable, flexible and timely production whether your custom requirement is small or large. Quality is key for us and continuous investment in equipment and automation enables us to achieve extremely high levels of repeatability. Certification to ISO standards confirms that we adopt a continuous improvement approach to service and quality assurance. Our goal is total customer satisfaction.

Wholesale InquirySHARE & EARN-Your Share, They Save, You Earn

Are you a shopaholic?

Would you like to earn money by just referring sequremall.com to friends or followers?

Now, take advantage of SEQURE Share Earn Programs. It's super simple! Just share www.sequremall.com to your friends / followers using social media and online interactions. Save them money while you earn commissions for everything they buy!

Share Earn is a simple money making program. There is NO-threshold, NO-cost, and NO-difficult for all users to earn real cash every day with just one share click. The commissions calculate basis on the price of the sharing merchandise, at least 5% commission.

The more you share, the higher you earn!

HOW IT WORKS

1.Sign up for a free affiliate account

2.Affiliate promotes sequremall.com on social platforms

3.Potential customer clicks on the posts

4.Customer orders at sequremall.com

5.Affiliate receives commissions

YOUR BENEFITS:

* 2%-8% * commission

YOUR FRIENDS BENEFITS:

1.Over 100 DIY tools to choose

2.Affordable prices

3.24/7 customer service and Live chat service